Product

MTVM – Lubricating Oil 500 ml - 99853-2

Produced in general accordance with the principles of ISO 17034 and ISO Guide 35, the Multi Test Verification Material (MTVM) Lubricating Oil provides certified values for multiple test methods and has been characterised using a network of competent laboratories to provide international traceability. It is a highly cost effective solution to help meet verification requirements for audited laboratories and those which comply with ISO 17025.

Multi Test Verification Materials (MTVMs) allow routine monitoring of instrument performance and are also particularly helpful in training personnel on new equipment and test methods. The purchase of MTVMs is recommended with new instrumentation to assist with installation and commissioning.

Incorrect determination of a result can have far reaching financial and safety implications. The growing use of automated instrumentation increases the possibility that incorrect results may go undetected and in addition the early indication of bias is a useful warning to minimise production ‘giveaway’.

Seta MTVMs are unique because, unlike most other certified reference material that are only suitable for validating a specific parameter/value, Seta MTVMs enable a user to validate different tests and instrumentation using the same sample material.

Certification: the Multi Test Verification Material (MTVM) Lubricating Oil is supplied with a certificate of measurement which gives the certified value for each test method covered by the material.

Suitable for use with a number of Seta instruments including the KV6 Viscometer Bath (84200-3) and the SetaCool-4 (94155-0).

Features

- Cost effective solution to verification requirements

- Cross-check instrument performance

- Assistance for operator training

- Supports full compliance to ASTM, IP, CEN and ISO test methods

- Supplied with full documentation including SDS

- Tamper evident security packaging

- 2 year shelf life from manufacture

Information

Details

| ISO 3104 | Kinematic Viscosity of Transparent and Opaque Liquids and the Calculation of Dynamic Viscosity |

|---|---|

| ISO 2909 | Calculating Viscosity Index from Kinematic Viscosity at 40 and 100°C |

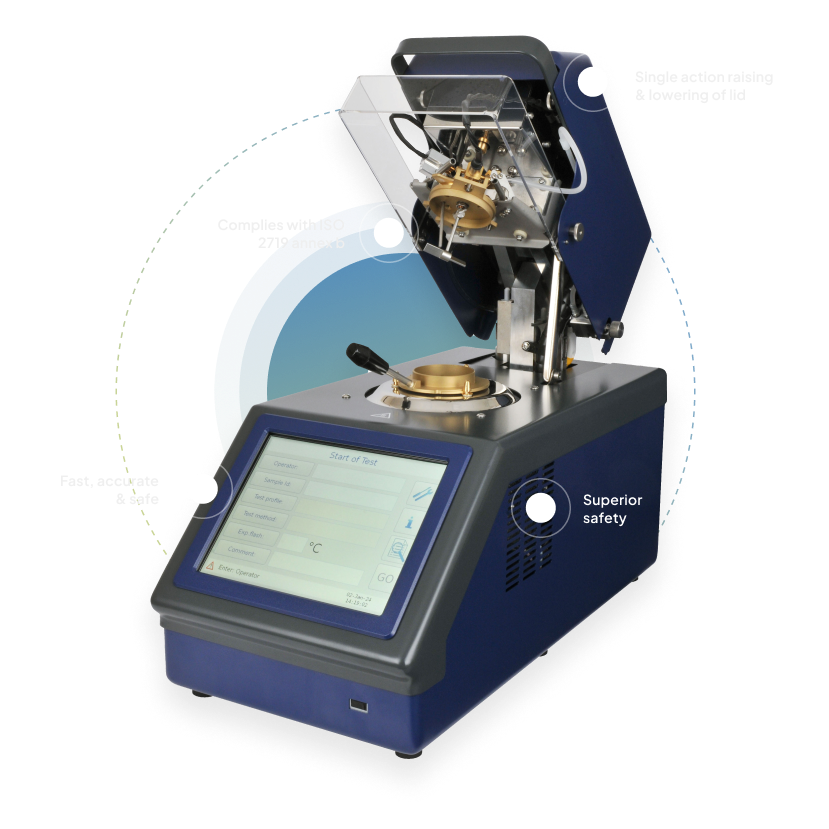

| ISO 2719 | Flash Point by Pensky-Martens Closed Tester |

| ASTM D97-IP15 | Standard Test Method for Pour Point of Petroleum Products |

| ISO 3016 | Pour Point of Petroleum Oils |

| ASTM D93 | Standard test methods for flash-point by Pensky-Martens closed cup tester |

| IP 34 | Determination of flash point - Pensky - Martens closed cup method (ISO 2719:2002) |

| IP 71 | Determination of kinematic viscosity |

| ASTM D4052 | Method for Density, Relative Density, and API Gravity of Liquids by Digital Density Meter |

| IP 365 | Density and Relative Density of Liquids by Digital Density Meter |

| ASTM D445 | Method for Kinematic Viscosity of Transparent and Opaque Liquids |

| ASTM D2270 | Standard Practice for Calculating Viscosity Index From Kinematic Viscosity at 40 and 100°C |

| ASTM D5185 | Method for Multi-element Determination of Used and Unused Lubricating Oils and Base Oils |

| ASTM D664 | Method for Acid Number of Petroleum Products by Potentiometric Titration |

| IP 226 | Petroleum products - Calculation of viscosity index from kinematic viscosity. |

Details

| Kin Vis 40 °C | 53 to 165 mm2/s Amount/test: 30 mL |

|---|---|

| Kin Vis 100 °C | 9 to 22 mm2/s Amount/test: 30 mL |

| Viscosity Index | 159 to 180 °C Amount/test: 60 mL |

| Pour Point | -49.1 to -33 °C Amount/test: 50 mL |

| Flash Point | 196 to 225 °C Amount/test: 80 mL |

| Density | 0.85 to 0.88 g/mL Amount/test: 2 mL |

| Total Acid Number | 1 to 5 KOH/g Amount/test: 5 mL |

| Zinc | 800 to 1275 mg/kg Amount/test: 5 mL |

| Phosphorous | 800 to 1600 mg/kg Amount/test: 5 mL |

| Calcium | 3000 to 5000 mg/kg Amount/test: 5 mL |

| CCCN Code | Tariff 38229000 |

Methods

Industries

Download product profile

To view our full range of products, download our latest Product Profile here.

Want to know more?

View our full range of products, or simply get in contact with us for more information.